Test, measure, clean and balance injectors for top performance.

- Test & Measure Injector Operation

- Measure Fuel Flow & Spray

- Ultrasonically Clean Injectors

- Renew Serviceable Injector Parts

- Retest and Match Injectors

Diagnosis of the complete fuelling system is now essential on today's fuel injected bikes. More often than not, the injectors are overlooked as the cause of any problems, being thought of as "solid-state" components. The usual "solution" to resolve problems with fuel injection systems is to make electronic adjustments - unfortunately this generally affects all injectors simultaneously and will therefore cause more problems than it "solves". At best, this will result in a poorly running bike, a dissatisfied customer and hours of wasted workshop time. At worst, expect a damaged engine or catalyst, a large bill and a lost customer. And the problem is still there! When you test the injectors, you can analyse their performance and see how defects affect performance. It's not only high-mileage bikes which are affected - as with carburettors, injectors are also susceptible to fuel going off during periods of non-use leaving deposits in the injector. Contamination and/or corrosion can reduce fuel flow or restrict the injector valve causing over fuelling. Spray pattern, atomization and the amount of fuel delivered can all be affected.

Features:

- LCD screen and sealed switch panel

- Injector pulse counter display

- Duty cycle display

- Up to 20,000 rpm

- Injector shot timer display

- Dynamic resistance check

- Before and after comparison

- Adjustable pressure

- Patented ultrasonic cleaning process

- Automatic cleaning cycles

- Suitable for all injectors - motorcycles, ATV, Marine etc.

- Essential for competition engines

- Approved by Bosch & Delphi worldwide

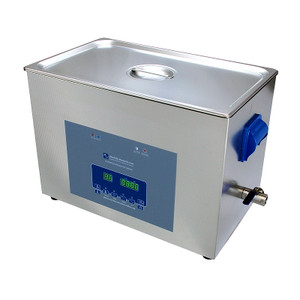

The ProBike Fuel Injector Tester is an instrument which can test & measure the injectors' droplet formation, atomization, efficiency and fuel delivery. All are visually and / or physically checked and tested as a starting point, rather than as a last resort. When problems are found, the injectors are cleaned in the supplied ultrasonic cleaning bath. The injectors mount in a special plate and are connected to the tester in order to operate them at high frequency during cleaning. After cleaning, the rubber sealing rings, plastic protection caps and filter baskets can be replaced (as applicable) before re-testing to ensure all the injectors are performing as a perfectly matched, balanced set.

You may say 'I've never had a problem with an injector', but without testing, how would you know? Problems do not always manifest themselves as an obvious misfire or poor running. Although carburettor cleaning is common practice, injectors are usually ignored despite the fact they are more vulnerable to contamination, being manufactured to much closer tolerances. The fact is that Injector servicing is necessary and it works, which is why this system is approved worldwide by Bosch and Delphi.

Testing & servicing injectors can be sold to the customer as an additional service, with the prospect of reduced future service bills and prolonged life of inlet & exhaust valves, piston rings, lambda sensors and catalytic exhausts. Matched sets of injectors can be sold as a premium tuning service - we have many customers including successful race teams and well known tuners who have proven the effectiveness of injector testing in competition.